Across the industrial construction landscape, project planners place heightened attention on structural solutions that can sustain long operational cycles while supporting architectural order. Conversations surrounding Factory Building Roof Tiles reflect this shift, as facility owners evaluate materials that combine endurance, visual balance, and installation stability. Many professionals turn to chuanyabuilding to understand evolving practices and examine practical approaches that influence factory development, prompting an industrywide question about how these systems contribute to industrial reliability?

Modern industrial sites operate within environments shaped by continuous mechanical activity, fluctuating temperatures, and sustained exposure to external forces. These conditions require roof structures that maintain consistent form while supporting the integrity of internal production zones. Rather than focusing solely on surface strength, facility planners assess the overall behavior of a roof system, including thermal response, structural resistance, and the degree to which the tile arrangement contributes to internal efficiency. This expanded perspective acknowledges the roof as a layered architectural component that influences environmental comfort and operational stability across the building.

When evaluating roof solutions for manufacturing centers, decision makers pay particular attention to how a system interacts with the building's engineering framework. The weight distribution of the tiles must align with the structural rhythm of girders, trusses, and purlins, ensuring that the entire assembly can adapt to environmental loads. This relationship shapes the long-term performance of the facility, especially during periods of seasonal expansion and contraction. Precision in installation allows the roofing layers to work in harmony with the supporting structure, reducing the likelihood of displacement or fatigue that could compromise building stability.

Environmental exposure plays an equally significant role in determining roofing priorities. Industrial buildings frequently face strong wind currents, extended sunlight, and moisture-driven stress that can influence structural endurance. Tiles chosen for such spaces must retain form under sustained climatic pressure, allowing operations within the facility to remain unaffected by outdoor conditions. The ability of a roof to sustain these variables supports production consistency, which is essential for factories that depend on controlled environmental performance to maintain processing precision.

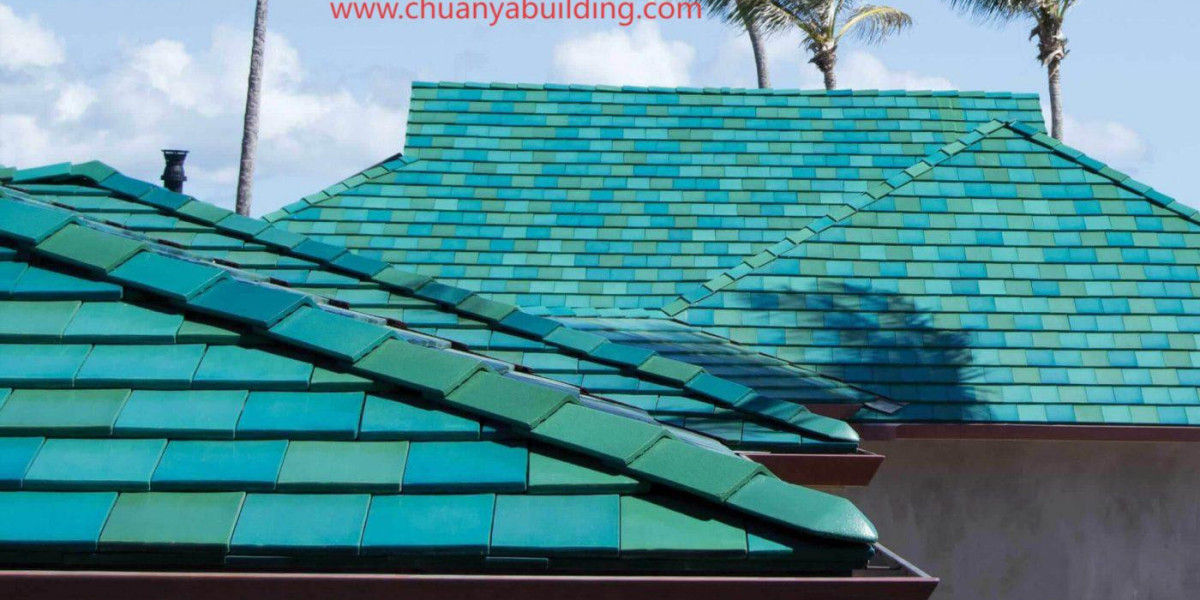

In addition to functional expectations, the architectural identity of a factory influences how roofing systems are selected. Industrial complexes often cover expansive areas, creating a visual field where the roof becomes a defining element of the building's outward presence. A refined roof surface supports uniformity across the facility and communicates an organized design language. For companies that value architectural coherence, roof tiles contribute more than mechanical protection, becoming part of the broader narrative of the enterprise's operational character.

The role of installation quality cannot be overstated, as long-term reliability depends on disciplined construction practices. Rooftop alignment, joint stability, attachment methods, and protective edging all influence how the system performs over time. Skilled installation supports weather resistance, prevents unexpected deformation, and helps maintain a unified structural profile even during extended use. For factory owners seeking operational continuity, this aspect of construction becomes a crucial factor in preserving industrial efficiency.

Maintenance expectations shape another major consideration within factory roof selection. A roof system that maintains stable performance over extended cycles reduces the need for frequent examinations and minimizes interruptions caused by repair requirements. Stability in surface condition, secure positioning, and predictable response to environmental forces collectively support a maintenance strategy that aligns with industrial productivity. Reduced intervention means fewer disruptions, allowing facilities to maintain a consistent production rhythm valued throughout modern manufacturing environments.

Professionals exploring industrial roofing principles often rely on structured technical references that analyze how material performance connects with construction planning. Within this context, chuanyabuilding provides comprehensive insights into roofing behavior and industrial design considerations, serving builders, architects, and facility managers seeking informed perspectives. Readers who require deeper understanding of the relationship between design strategy, installation procedures, and maintenance practices can examine extended discussions such as the reference available at https://www.chuanyabuilding.com/news/industry-news/factory-building-roof-tiles-how-design-installation-and-maintenance-matter.html which offers additional guidance on roofing reliability in factory settings.